How to Avoid Air Compressor Service Repair in Glasgow

Written on November 14, 2022 By Gregory Dinnell in Skills, Technology

If your business relies on compressed air equipment and services, there are several steps you can take to prevent problems avoiding unnecessary repairs of a compressor service Glasgow. These include choosing the right service air compressor service provider, identifying the problem, and performing the repair. Following the manufacturer’s recommendations will also ensure that your equipment remains under warranty. Read on for our top tips for maintaining a quality air compressor.

Compressed air system maintenance

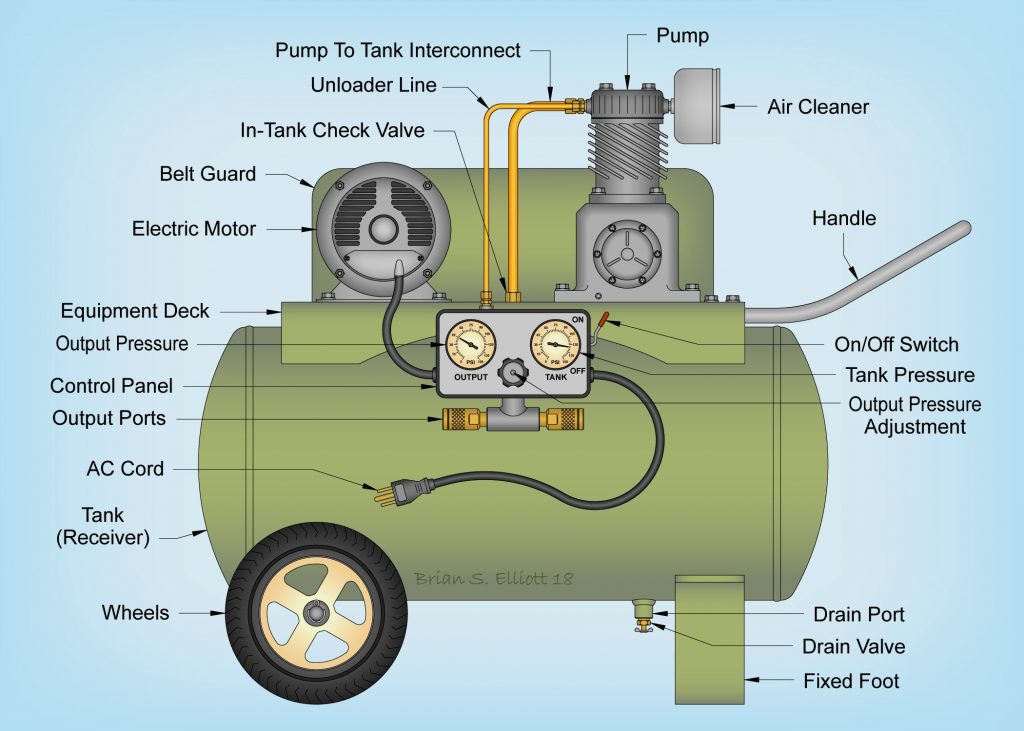

Regular air system maintenance is essential for your compressed air system to operate efficiently and safely. It should include inspections of air and oil leaks, pressure relief valves, and temperatures, along with voltage levels, vibration, and air dryer performance. The compressor should also be checked for proper belt tension and alignment. The compressor’s pipes and air receiver tanks should also be checked for leaks and integrity.

A professional technician is often recommended for this work. A skilled technician can identify emerging problems before they become severe. For example, even a simple air filter or belt replacement can keep your compressed air system operating as efficiently as possible.

Choosing a service provider

When you require a repair air equipment compressor service Glasgow, choosing a company with a proven track record is best. You need a company with technicians who have experience with the specific types of equipment you use, as well as fast response times. A company with an excellent track record will also provide preventative maintenance plans and installation services.

You are choosing a service provider that can provide you with the advanced technology you need to keep your equipment running at peak performance. In addition, a company with the latest in monitoring and maintenance equipment will respond to problems quickly, protecting your employees and your business.

Identifying a problem

One of the first steps in repairing compressed air equipment is identifying the problem. There may be some potential causes. One of the most common reasons for a problem is a faulty component. It could be something as simple as a dirty filter, but it could also be something more serious, such as a broken piston or damaged intake filter.

Another common problem is a leaking component. If you notice a lack of pressure when the compressor is turned off, the check valve is likely faulty. You can repair this problem by removing the check valve assembly and cleaning the defective components. Another common problem could be a foul drain or a false condensate trap. Finally, check for worn components in the air compressor, especially the connecting devices.

Performing a repair

Performing a repair on compressed air equipment is essential in preventing air compressor breakdowns and maximizing your equipment’s performance. Downtime can cost a company hundreds of thousands of dollars per hour, so preventing these problems is critical. Fortunately, you can take several simple steps to avoid air compressor breakdowns and maximize your equipment’s lifetime.

The first step in performing a repair is identifying the problem. If the problem is simple, such as a faulty air filter, the next step is to replace the air filter. Then, lubricate the parts. After lubricating and replacing the air filter, you should check the air compressor for minor problems.

Gregory is a content creator with a focus on photojournalism, capturing the mood and atmosphere of local events and everyday moments.